Modern day conveniences in and around my rural Sampson County homestead – Circa 1895-1925

A “convenience” is defined as something that increases comfort or makes work less difficult. In 1895, my grandfather, G.W. Bullard, embraced the latest “conveniences” when he built and maintained his home in the Hayne community of Sampson County near Roseboro. All lumber, shingles and brick for the cellar came from our place except the brick for the house’s chimney, which were bought elsewhere.

Longleaf pine was common and since the turpentine industry was coming to a close around 1900 in the area, the trees were expendable. The last longleaf chipping for turpentine was in 1907 on our place. Around 1900, longleafs were cut and many were burned at “log rollings” to allow for the land to be cleared for crops. The naval stores industry had begun to move southward by this time.

Our homegrown timber was hauled by mule and wagon to Cedar Creek in Cumberland County to be planed and dressed. The shingers were homegrown, but not hand riven. I don’t know whether the shingle mill was on our place.

My grandfather Bullard (1856-1919) was not considered a wealthy man, but he did accumulate around 1,000 acres of land and successfully supported 10 children. My father, A.J. Bullard Sr., was the youngest child and inherited the homestead on which my sister, Betty, and I were reared.

Grandfather was a progressive man, and with the assistance of a son, Dr. T.P. Bulard, he was able to acquire an array of “conveniences” that proceeded those of most contemporary neighbors by half a century.

My purpose with this writing is to elaborate on many of these conveniences, their function and the approximate years they were implemented. Keep in mind that this period was 40 to 45 years before electricity was introduced into the area.

Central Lighting. It was plumbed in by network of galvanized piping when ourhouse was built. These pipes extended beyond te house itself to the general store next door, which had a night light on a post in front, but no piped-in lights inside.

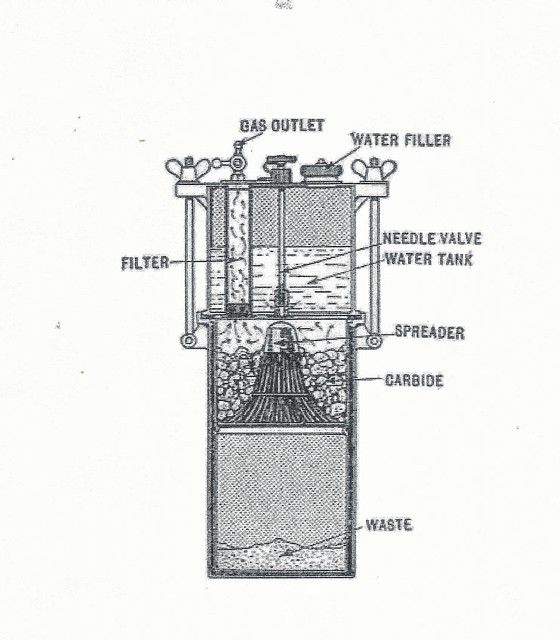

Each fixture was lighted and extinguished individually with no pilot lights. These were so-called gas lights and gave good lighting. The active gas was acetylene (C2H2), a colorless, highly flammable or explosive gas. Another even more popular use of acetylene was in torces for metal cutting and welding and in various hand and head lamps.

How was this gas generated? These “systems” required a “plant” or source of the gas. Our plant was in the brick cellar and consisted of two stainless steel tanks with covers hooked to the galvanized pipe system. The acetylene gas was created by mixing calcium carbonate with water in the tanks. The calcium carbonate powder came in bags. Acetylene gas to power lighting systems wasn’t introduced in the southeast until 1894, so ours was a very early system installed in 1895. I have seen a gas lighting system that dated back to the late 1700’s. The gas for it was created by burning fat lightwood stumps. I do not know what gas that produced.

In this same brick cellar was a “root cellar” with steps leading down six feet. Here canned goods, fruits and vegetables were stored without freezing or overheating. These earthen cavities usually maintained a temperature of 50-55 degrees F. Leakage was no problem since the root cellar was already sheltered by the brick cellar roof.

Telephone: As with the carbide lights, it appeared the telephone was wired in when the house was built. It was a wall phone on our downstairs hallway wall, but that phone was long gone when I was growing up. I was shown the holes where it was wired in. This was long before AT&T. For this first service, the locals put up poles and lines and the service was only within the neighborhood.

It was later expanded to include Cedar Creek, Autryville, Turnbull, Stedman, White Oak and Roseboro, and in 1925 a Roseboro Exchange of the Roseboro and Fayetteville Telephone Company issued a directory. My cousin, Virginia Bullard Vinson, gave me a copy of this directory. Many familiar names of old were present along with sponsors in that directory. Monthly telepone rates were 50 cents a month for all rural phones and $1.50 for business phones. Later, Carolina Telepone and Telegraph Company bought these smaller lines out.

Running water: Before electricity, gasoline pumps or paralleling windmills. Preceding such pumps, water was raised manually by use of hand pumps, well tackles and well sweeps Hydraulic rams were known in England in the 1700’s and by the late 1800’s were introduced in the United States. The principle is to raise a column of water with a valve closing and without wind power , electricity or gasoline power. Years ago, I saw two hydraulic rams and as the valve closes it makes a clanking nosie similar to hog feeders and tobacco hand transplanters.

We had such a “ram” around 1915. Again, my uncle, T.P. Bllard, engineered and installed it. To set it up, an overflow was piped down 64 feet deep in a soggy “branch” about 450 feet from our back yard. The “ram” propelled water via a pipe, uphill to a water tank in our back yard. From this tank, gravity took over to feed a solar heated drum for showers and running rater for drinkning and washing clothes. All of this was done without electricity, a windmill, gasoline engine or manual labor.

Electricity would not come for another 25 years. This ram gave way to electric power and I heard the device was taken out by Uncle T.P. and moved to the wooded branch beside his home outside Roseboro. His widow, my aunt Lula, said I could have it, but I couldn’t find it in the overgrown area around the branch, where she said it had been placed.

Tractor: Again, Granddad had to be on the cutting edge. He purchased a steel tread International “Titan” tractor in 1918. It came by freight train to the depot at Hayne, and my first cousin, Roland Bullard (then age 6), described himself as one of six young lads who somehow rode it home along with the driver. I never heard how much the tractor cost.

Granddad’s intent was to then own a superior land breaker and disker. Unfortunately, this was not be because the tractor was so and ungainly. My dad, then aged 15, said it “couldn’t be turned around in a 10-acre field.” My grandfather’s 10-12 mules were to see no rest in the ensuing years, and the “Titan” was relegated to powering his cottong press and gin at Hayne.

Pea sheller. It seems tha any implement that saved manual labor was welcomed. Again, my uncle T.P. Bullard came to the fore! In 1919, he invented a pea sheller and patented it in the United States and Canada. It met with reasonable success but I never heard the number he sold or the price. It did mangle some peas but did a credible job for non-perfectionists. It was of galvanized metal and stood on legs just over knee hight. It rested in the little closet in our main hall under the stairs.

Radio. Before 1925, my family purchased a large radio ( I never saw it), but it needed batteries to run it in lieu of electricity. To accomplish this, a wind charger (small windmill) was installed atop the roof. The installers were my cousin Roland Bullard and another neighbor of a mechanical bent, Halbert Sessoms. This worked well!

Vicrola. Following our radio, a Victrola was purchased. By my time, the Victorla was gone but residual, thick 78 RPM records lay around. My sister and I, with little appreciation for music at that time, used to sail them at each other outside when our parents were in the house or gone. Luckily our aim was off or major injury would have occurred.

Blacksmith shop: When I was growing up, this had been abandoned, but still stood. I didn’t know of any others in the neighborhood but would guess Roseboro had one. I never heard who the chief blacksmith was, but a tenant on our place, young Lonnie Sessoms, worked there occassionally, and he told me he sharpened hoes, axes and knives on the pedal grind stone. This shop had a front door on metal sliders and a furnace and bellows. Wrought iron tools such as plow points, shanks and mule shoes, were forged and repaired there on a huge anvil which I still have.

I beliee I have covered most of these “conveniences” that were functional in the day. Although many preceded my time,there were residuals left over for me to ponder and to remember through the years. I’m glad I listened to my parents, neighbors and relatives an dnow have this information to pass along to those interested.